Products

Contact Information

Address: No. 106, Lianxi West Road, Lianxi Industrial Park, Jiading District, Shanghai

Telephone:021-69512716

Mailbox:13310035985@163.com

Glass bottle drop filling equipment

This machine is mainly used for 20-1000ml round bottles or shoulder shaped bottles of various materials inside and outside cleaning operations.

Keywords: Glass bottle drop filling equipment

Classification:

Product Details

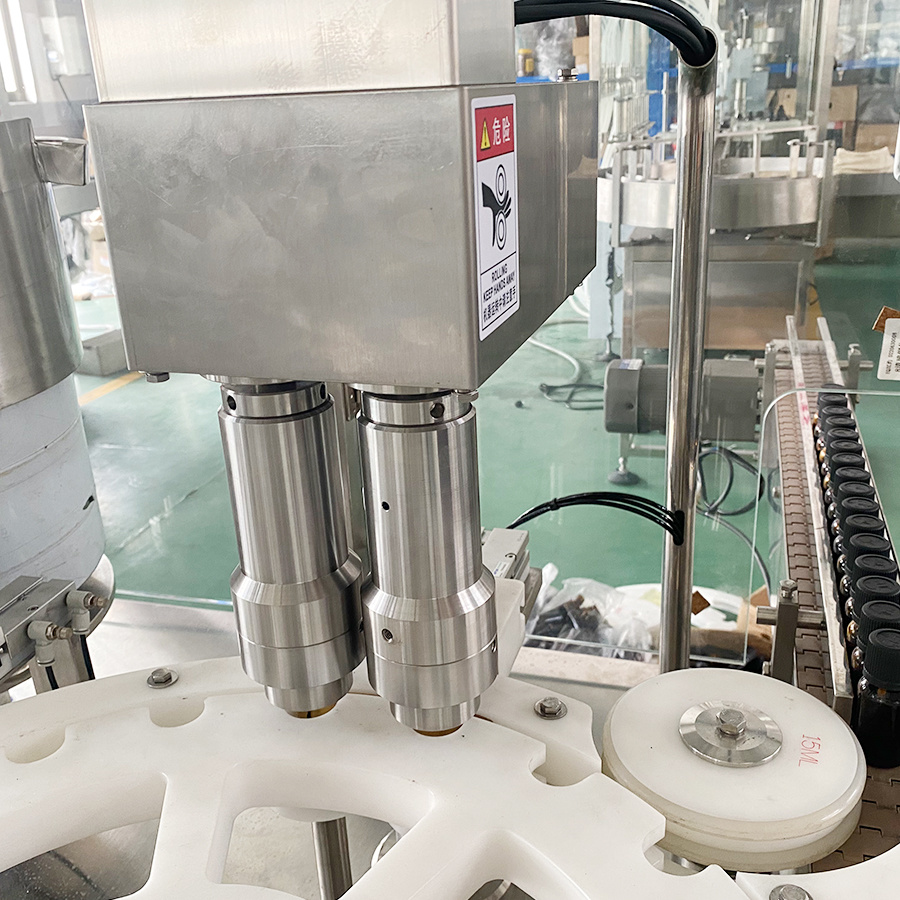

▍Working principle

The ZCG-II filling, capping and capping machine is mainly suitable for liquid filling, capping and capping operations in the pharmaceutical, health care products, and daily chemical industries. This machine adopts advanced manipulator capping method, which has the characteristics of simple and convenient specification change; touch screen and PLC intelligent control, simple operation and convenient human-machine dialogue; it has the function of not filling when the bottle is missing, and stopping when there is no bottle, which can complete bottle unscramble, bottle feeding and filling. Assembling, plugging, capping and capping processes are especially suitable for mass production. The work surface of this machine is protected by stainless steel material, and the whole machine complies with GMP requirements.

▍Number of major technology participants

|

serial number |

project |

Technical Parameters |

|

1 |

production capacity |

30-50 bottles/minute |

|

2 |

Adapt to specifications |

10-100ml (need to replace mold) |

|

3 |

Number of filling heads |

2 heads or 4 heads |

|

4 |

Filling accuracy |

±1% |

|

5 |

Number of heads added with plugs and caps |

Single head (robot) |

|

6 |

Number of capping heads |

single head |

|

7 |

Production pass rate |

≥99.5% |

|

8 |

power supply |

220V、50Hz |

|

9 |

Gas source |

0.3~04kfg/cm2 |

|

10 |

Air consumption |

5m3/h |

|

11 |

power |

3.0KW |

|

12 |

weight |

About 850kg |

|

13 |

Dimensions |

2400×1150×1700mm |

▍Number of major technology participants

|

serial number |

project |

Technical Parameters |

|

1 |

production capacity |

70-90 bottles/minute |

|

2 |

Adapt to specifications |

10-100ml (need to replace mold) |

|

3 |

Number of filling heads |

4 heads, 6 heads, 8 heads |

|

4 |

Filling accuracy |

±1% |

|

5 |

Number of heads added with plugs and caps |

Double head (robot) |

|

6 |

Number of capping heads |

double head |

|

7 |

Production pass rate |

≥99.5% |

|

8 |

power supply |

220V、50Hz |

|

9 |

Gas source |

0.3~04kfg/cm2 |

|

10 |

Air consumption |

5m3/h |

|

11 |

power |

4.0KW |

|

12 |

weight |

About 950kg |

|

13 |

Dimensions |

3200×1300×1700mm |

▍Main electric appliance arrangement

|

Name |

model |

Origin |

brand |

|

Miniature Circuit Breaker |

OSMC32NIC10 C16 |

France |

Schneider |

|

Miniature Circuit Breaker |

OSMC32NIC10 C10 |

France |

Schneider |

|

AC contactor |

LC1 E09 |

France |

Schneider |

|

small relay |

RXM2LB2BD DC24V |

France |

Schneider |

|

The electromagnetic valve |

4V210 08B DC24V |

Taiwan |

AirTAC |

|

touchscreen |

SMART700IE |

Germany |

Siemens |

|

Main motor |

M2BAX 80MB4 |

Switzerland |

ABB |

|

sensor |

FX-100 |

Japan |

Matsushita |

|

switching power supply |

NES-100-24 |

Taiwan |

MEAN WELL |

|

Frequency converter |

FR-CS80-042-60 |

Japan |

mitsubishi |

|

PLC |

FX3SA-30MT |

Japan |

mitsubishi |

|

servo motor |

HG-SN152(B)J-S100 |

Japan |

mitsubishi |

|

server Driver |

MR-JE-152A |

Japan |

mitsubishi |

Here is the title one h1 placeholder text

Related Products

Product Consulting