Products

Contact Information

Address: No. 106, Lianxi West Road, Lianxi Industrial Park, Jiading District, Shanghai

Telephone:021-69512716

Mailbox:13310035985@163.com

10-100ml vial filling equipment

This machine is mainly used for 20-1000ml round bottles or shoulder shaped bottles of various materials inside and outside cleaning operations.

Keywords: 10-100ml vial filling equipment

Classification:

Product Details

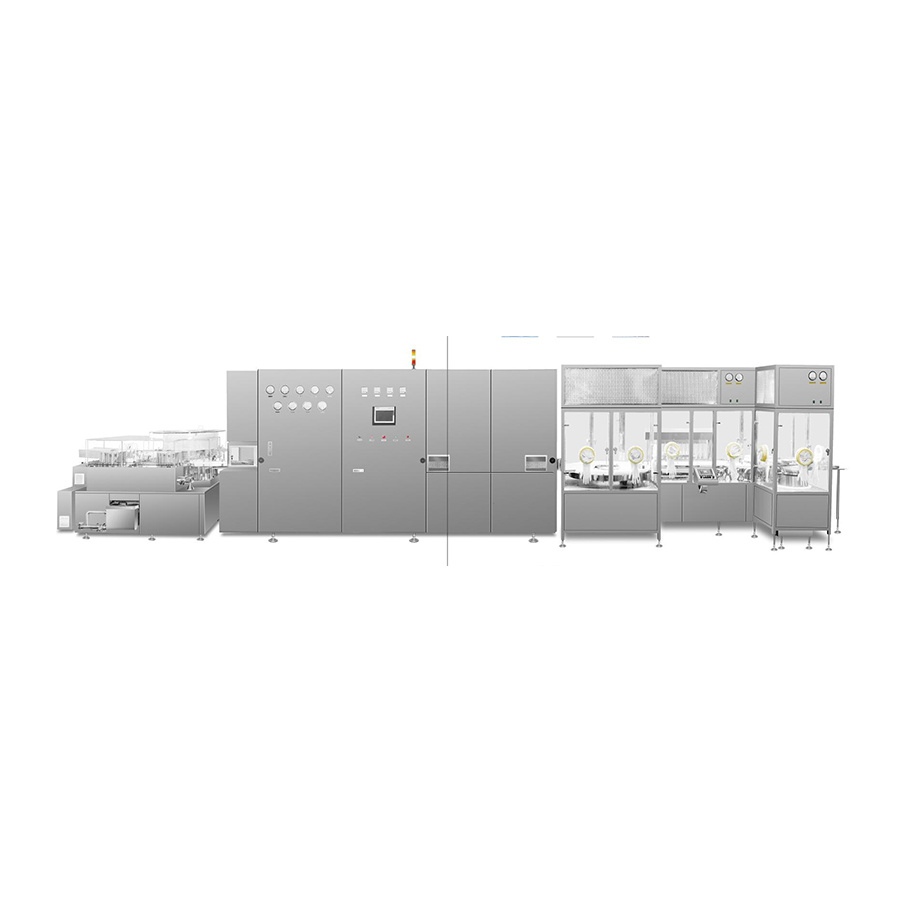

This production line is suitable for the production of 10-100ml vial washing, drying and filling linkage line. Different equipment solutions are recommended according to bottle type and production capacity.

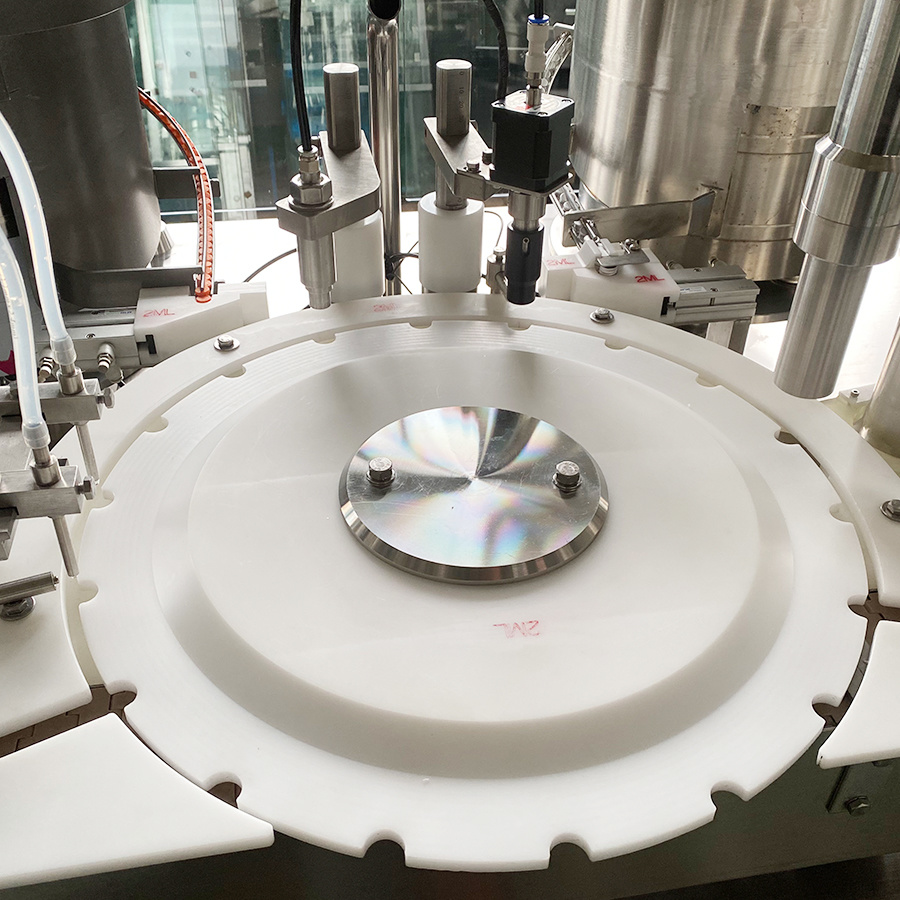

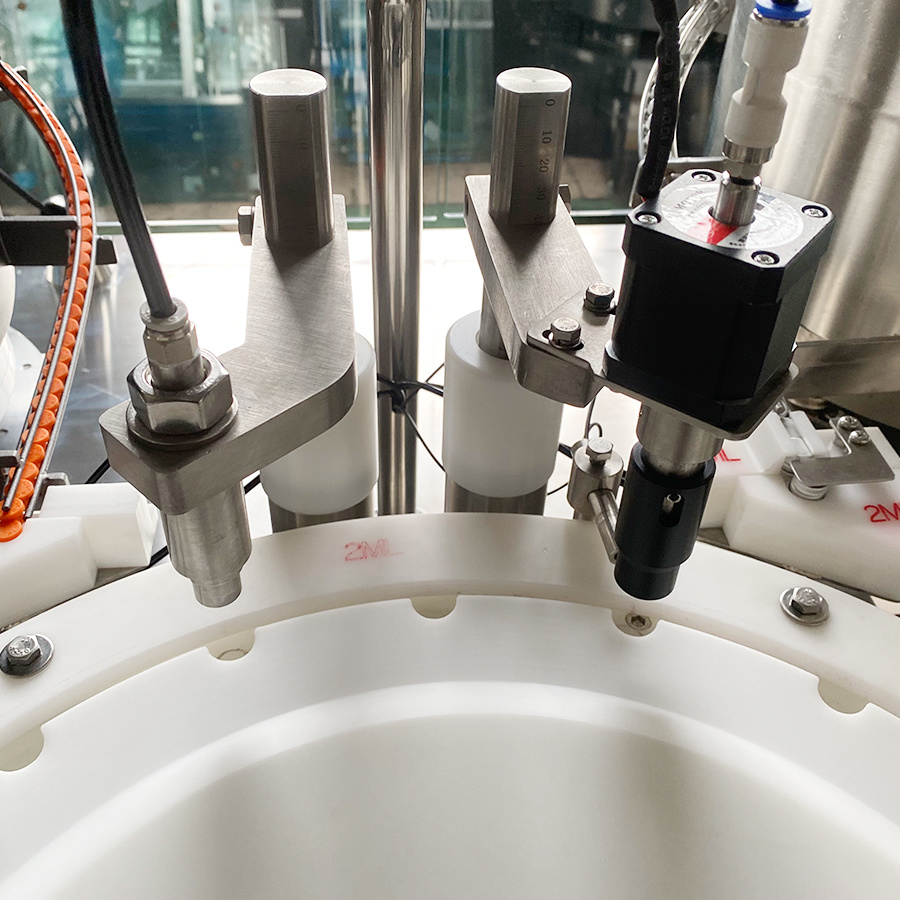

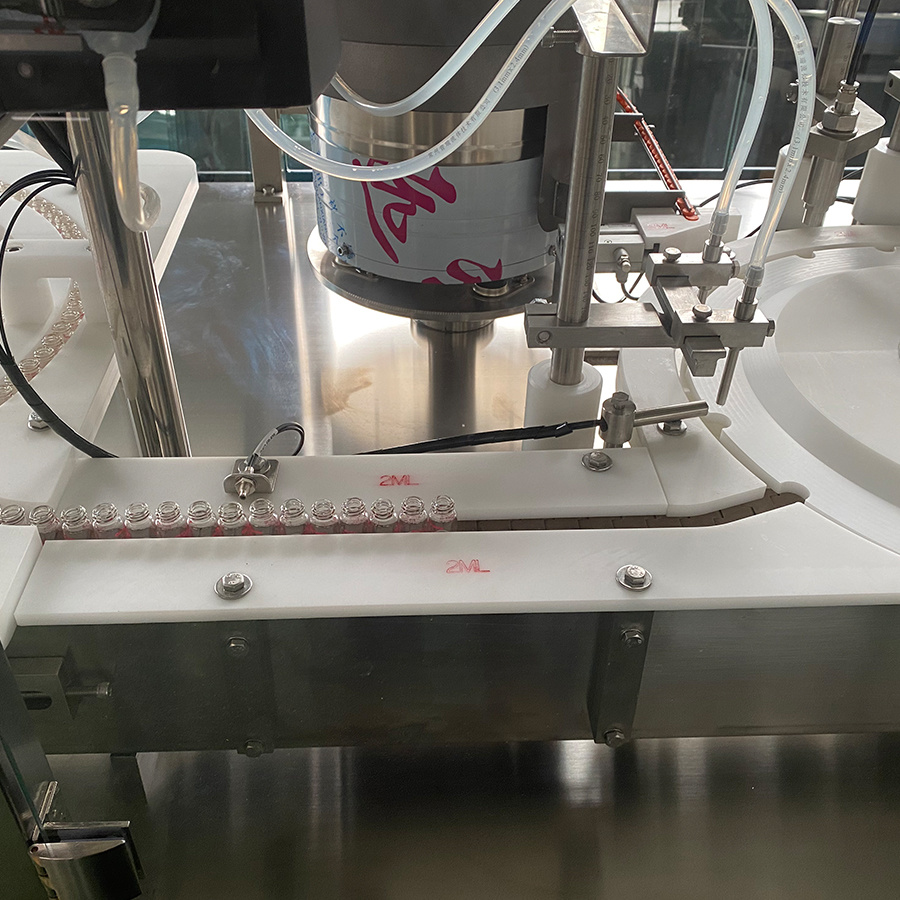

After ultrasonic washing and hot air circulation sterilization, the bottles enter the filling room through 100-level laminar flow protection. The filling and corking machine has 100-level laminar flow protection. The filling uses a servo peristaltic pump or servo Ceramic pump structure, the stoppering adopts the manipulator to take out the stopper structure, the stoppering is more accurate. After filling and stoppering, it is transported into the capping room. The capping machine adopts a three-knife capping structure, with a cap or no detection alarm function, and the capping head moves up and down to complete the process. Capping operation.

The entire unit is controlled by a programmable controller (PLC) with a programmable human-machine interface, which can be controlled in linkage and stand-alone operations. The working status of each part can be automatically monitored and displayed, and will automatically stop when a fault occurs. Shutdown ensures the normal operation of the entire unit and is more in line with GMP requirements.

Here is the title one h1 placeholder text

Related Products

Product Consulting