Products

Contact Information

Address: No. 106, Lianxi West Road, Lianxi Industrial Park, Jiading District, Shanghai

Telephone:021-69512716

Mailbox:13310035985@163.com

Sterile eye drops filling equipment

This machine is mainly used for 20-1000ml round bottles or shoulder shaped bottles of various materials inside and outside cleaning operations.

Keywords: Sterile eye drops filling equipment

Classification:

Product Details

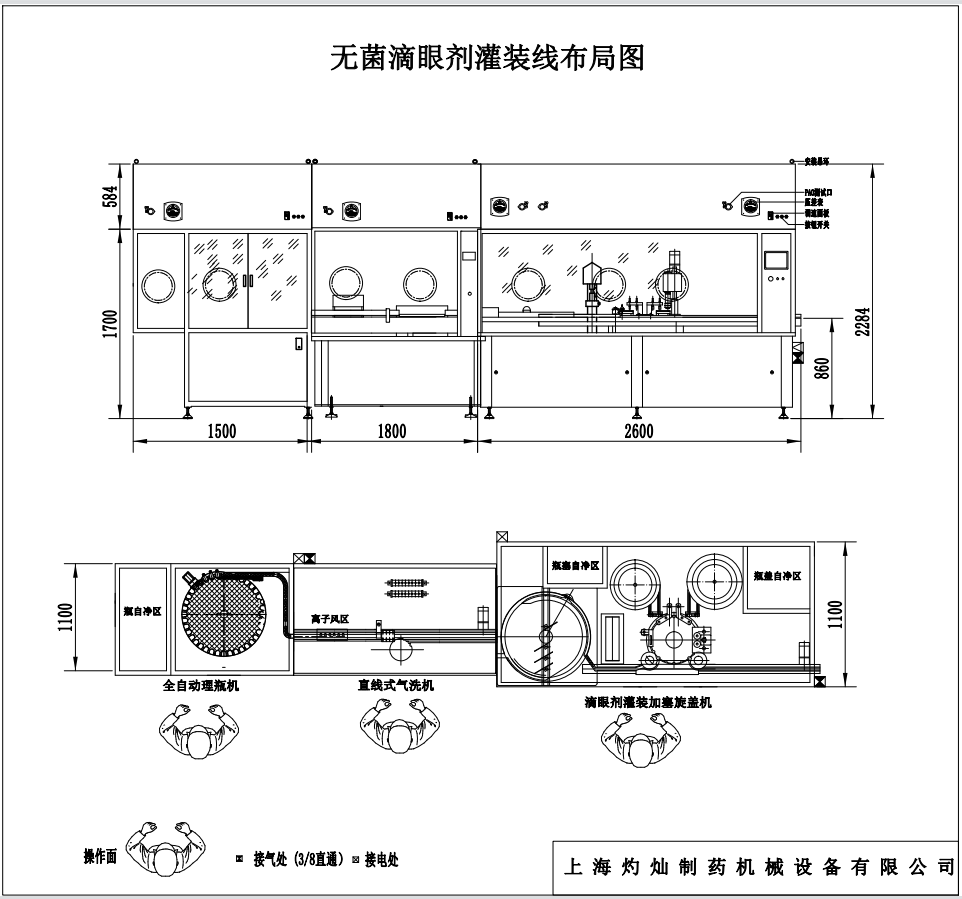

This equipment is suitable for filling production line operations for sterile eye drops three-piece bottle sets. The sterilized bottles are manually transferred to the self-cleaning area of the bottle unscrambler and then go through the automatic bottle unscrambler and linear air washing. After the machine and the eye drop filling, stoppering and capping machine enter the outsourcing room to complete the labeling and cartoning operations;

This linkage line is a new generation of production linkage developed based on the current situation of eye drop production. unit. The machine adopts the modular design principle, with novel design concept, reasonable and advanced mechanism, high degree of automation, stable and reliable operation, high production efficiency, and high degree of electromechanical integration. The entire linkage machine component is divided into bottle unscrambler, deionized air, air washing, eye drop filling, stoppering and capping work areas, which can accurately and reliably realize its functions. It can be used as a stand-alone machine or in linked production. It can complete the production processes of fully automatic bottle sorting, inverted bottle removal, filling, corking, capping, and capping. It can be completely suitable for the production of eye drop bottles.

The entire unit is controlled by a programmable controller (PLC) with a programmable human-machine interface, which can be controlled in linkage and stand-alone operations. The working status of each part can be automatically monitored and displayed, and will automatically stop when a fault occurs. Shutdown ensures the normal operation of the entire unit and is more in line with GMP requirements.

The main technical parameters:

|

serial number |

project |

Technical Parameters |

|

1 |

production capacity |

≥40 bottles/minute ≥80 bottles/minute |

|

2 |

Adapt to specifications |

2~15ml eye drops round bottle |

|

3 |

Filling method |

Servo peristaltic pump |

|

4 |

Number of filling heads |

Double or four heads |

|

5 |

Filling accuracy |

±1% |

|

6 |

Number of heads added with plugs and caps |

Single head or double head (robot) |

|

7 |

Number of capping heads |

Single or double head |

|

8 |

Production pass rate |

≥99.5% |

|

9 |

power supply |

220V、50Hz |

|

10 |

Gas source |

0.3~04kfg/cm2 |

|

11 |

Air consumption |

5m3/h |

|

12 |

power |

3.0KW |

|

13 |

weight |

About 1000kg |

|

14 |

Dimensions |

2600×1150×1700mm |

Here is the title one h1 placeholder text

Related Products

Product Consulting